Quick guide for successfully setting up an optical measurement system in a production environment

Quick guide for successfully setting up an optical measurement system in a production environment

Blog Article

Recognizing Exactly How Optical Measurement Solution Enhance High Quality Control Processes

When you're looking to enhance quality control processes, recognizing optical dimension systems is important. Let's check out the vital aspects that make optical measurement a game-changer in quality administration.

The Basics of Optical Dimension Solutions

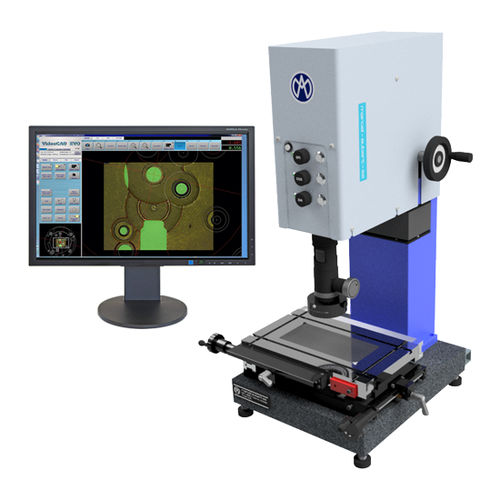

Optical measurement systems play a crucial role in ensuring item top quality across numerous industries. These systems utilize light-based innovations to gather precise data about physical attributes, such as dimensions, surface area coating, and color. By employing lasers, sensors, and electronic cameras, you can achieve non-contact dimensions that minimize the risk of destructive fragile products.

Recognizing the fundamentals of these systems is essential for efficient top quality control. They operate principles like refraction, diffraction, and representation, allowing you to evaluate various materials and forms. The accuracy and rate of optical dimensions make it possible for real-time tracking, which aids you recognize flaws early in the production process.

Furthermore, these systems can be incorporated with software for improved information analysis, producing an extensive quality administration strategy. By leveraging optical measurement systems, you not only improve productivity yet additionally assure your products meet rigorous quality requirements, ultimately enhancing consumer contentment.

Kinds Of Optical Dimension Technologies

Various sorts of optical measurement modern technologies are offered, each created to satisfy details needs in quality control. You may encounter laser triangulation, which determines range by assessing the angle of a reflected laser beam. This innovation is optimal for capturing precise dimensions in 3D area.

One more choice is structured light, where you predict a series of light patterns onto a surface to produce a thorough 3D design. This technique works well for intricate geometries.

After that there's interferometry, which can detect minute modifications in surface profiles by analyzing the interference patterns of light waves. This is especially helpful for applications calling for nanometer accuracy.

You might likewise consider optical coherence tomography, which provides high-resolution photos of inner features without harming the things. Each modern technology offers various requirements, so choosing the ideal one is necessary for accomplishing highest control results.

Secret Advantages of Optical Dimension in Top Quality Control

When it concerns top quality control, leveraging optical dimension modern technologies can considerably boost precision and performance. These systems permit you to record thorough measurements promptly, reducing the time needed for examinations. You'll see that optical dimensions can recognize even the smallest defects that could go unnoticed with conventional approaches, making sure product uniformity.

In addition, utilizing optical dimension systems commonly results in reduced waste and revamp, as you catch concerns early in the manufacturing procedure. You'll likewise value the non-contact nature of lots of optical methods, which lessens damages to delicate parts during evaluation. This flexibility enables a broader series of applications throughout different products.

With real-time information collection, you can make educated choices promptly, improving your quality control procedures (optical measurement system). Eventually, including optical measurement into your high quality control strategy not only increases performance but likewise enhances client contentment by delivering higher-quality products consistently

Exactly How Optical Measurement Solution Improve Precision and Precision

Optical measurement systems increase accuracy and precision by improving dimension resolution, permitting you to spot even the tiniest variants. With real-time information analysis, you can make prompt changes and decisions, guaranteeing your processes stay on track. This combination not only boosts item top quality yet also improves your high quality control efforts.

Improved Dimension Resolution

By leveraging innovative modern technologies, optical measurement systems substantially boost dimension resolution, leading to improved precision and precision in quality assurance. These systems use innovative formulas and high-resolution cams to capture minute details that traditional approaches frequently miss. You'll discover a significant difference in the clearness of measurements, permitting you to determine even the least inconsistencies from specs. This boosted resolution helps eliminate guesswork, providing you with information that's both workable and dependable. Therefore, you can make even more educated decisions and keep tighter tolerances in your processes. Inevitably, improved measurement resolution not only improves product top quality but also enhances resource utilization, making certain that you satisfy consumer expectations constantly.

Real-Time Data Evaluation

Although traditional measurement systems frequently count on delayed data processing, real-time information analysis in optical measurement systems reinvents the way you keep an eye on top quality. By providing instant feedback, these systems enable you to discover inconsistencies and variances as they take place, enabling swift corrective actions. You'll experience enhanced accuracy considering that you can promptly contrast measurements against predefined requirements. This gets rid of uncertainty and reduces the risk of defects slipping with. Furthermore, real-time data assists you gather valuable understandings with time, fine-tuning your quality control processes. With this advanced innovation, you'll improve both precision and effectiveness, making sure that your items constantly satisfy high criteria. Embrace real-time evaluation, and enjoy your quality assurance efforts skyrocket to new elevations.

Incorporating Optical Measurement Into Existing Quality Assurance Processes

Incorporating optical measurement right into your existing quality assurance processes can considerably enhance precision and efficiency. By integrating optical measurement systems, you can simplify data collection, decreasing human mistake while enhancing the speed of examinations. Begin by identifying bottom lines in your production line where optical dimensions will provide one of the most value.

Following, train your group on the new innovation, guaranteeing they comprehend exactly how to utilize the systems properly. This training will aid them interpret results swiftly and properly.

You ought to likewise develop a method for incorporating optical information into your existing high quality management software program. This assimilation enables for real-time analytics and reporting, enhancing decision-making.

Regularly examine the information and feedback from your team to determine any type of areas for renovation. With these actions, you'll not just boost your quality assurance procedures yet likewise promote a culture of continuous renovation within your organization.

Instance Researches: Effective Execution of Optical Measurement Solutions

In this area, you'll explore just how optical dimension systems have transformed quality assurance in markets such as aerospace and automobile production - optical measurement systems. You'll see real-world instances of just how these technologies enhanced accuracy and efficiency. These study highlight the substantial advantages of incorporating optical systems into production processes

Aerospace Sector Applications

As the aerospace sector deals with increasing demands for accuracy and performance, companies are turning to optical dimension systems to improve their top quality control processes. A leading airplane supplier incorporated optical dimension technology to evaluate turbine blades, lowering examination time by 50% while enhancing precision.

Automotive Manufacturing Success

Optical dimension systems have also made substantial strides in the auto manufacturing field, where precision is essential to lorry performance and safety and security. BMW incorporated optical dimension for body assembly, making sure components fit completely, which reduced rework and boosted production performance. These instance studies demonstrate just how optical dimension systems encourage you to achieve tighter resistances, reduce waste, and boost total product high quality.

Future Trends in Optical Measurement and Quality Assurance

While improvements in technology remain to reshape the production landscape, the future of optical dimension and quality assurance looks appealing - optical measurement system. You'll see a considerable shift in the direction of automation and AI assimilation, allowing systems to analyze information in real-time. This advice implies quicker decision-making and lowered human error, eventually improving item top quality

Furthermore, as 3D imaging modern technology boosts, you'll benefit from more precise measurements of complex geometries, making it easier to maintain tight resistances. The increase of cloud-based remedies will certainly additionally permit you to access information from another location, helping with partnership and improving operations.

In addition, sustainability will play an important function in future developments. Expect optical measurement systems to focus on energy performance and waste decrease, lining up with discover this worldwide ecological goals. By accepting these patterns, you can guarantee your high quality control processes remain cutting-edge, helping your organization grow in a significantly competitive market.

Frequently Asked Inquiries

What Industries Advantage Most From Optical Dimension Equipments?

You'll discover sectors like manufacturing, aerospace, and automobile benefit most from optical measurement systems. These sectors count on specific dimensions for quality control, guaranteeing products fulfill rigid requirements and enhancing overall functional effectiveness.

How Do I Choose the Right Optical Dimension System?

To choose the appropriate optical dimension system, evaluate your specific demands, think about the kind of measurements you need, assess the system's precision, and assure it fits your budget plan and functional demands.

What Prevail Obstacles in Carrying Out Optical Measurement Systems?

You'll encounter difficulties like assimilation with existing systems, guaranteeing exact calibration, educating staff effectively, and taking care of costs. Recognizing these obstacles early helps you develop methods to conquer them and effectively implement optical measurement systems.

Are There Training Resources Available for Optical Dimension Technologies?

Yes, there're numerous training sources readily available for optical measurement innovations. You can discover on the internet training courses, webinars, and workshops supplied by sector specialists or companies. These sources can help you efficiently execute and use these sophisticated systems.

Just How Do Optical Dimension Solutions Contrast to Standard Dimension Techniques?

Optical measurement systems provide higher precision and speed contrasted to typical methods. They reduce human mistake, allow non-contact dimensions, and supply real-time data analysis, making them extra efficient for numerous applications in quality assurance.

Final thought

Optical measurement systems improve precision and accuracy by enhancing measurement resolution, permitting you to spot also the smallest variants.By leveraging innovative innovations, optical dimension systems substantially enhance measurement resolution, leading to improved accuracy and precision in quality control.Although standard measurement systems typically depend on delayed information processing, real-time information analysis in optical dimension systems changes the way you keep track helpful resources of top quality.As the aerospace industry deals with raising needs for precision and performance, companies are turning to optical measurement systems to enhance their quality control processes. How Do Optical Measurement Systems Contrast to Typical Dimension Approaches?

Report this page